2010

TECnology Hall of Fame

Audio Innovations

that Changed the (Pro Audio) World

By George Petersen

To expand the

scope of the TEC Awards, the TECnology

Hall of Fame was created in 2004 to spotlight

important innovations from the long and

rich history of the pro audio industry.

Each year, inductees are selected by

a committee of more than 50 industry

leaders, engineers, producers, designers,

educators, journalists and historians,

with the only “rule” being

that any selection must be at least 10

years old.

Once the results

are in, I research and write narratives

that put each into a historical context.

The process isn’t necessarily

easy. Many manufacturers are long since

out of business. At some companies, no

one remains who has any knowledge of the

product. Worst of all, the history of pro

audio—our very lineage—is woefully

neglected and sources are scarce, if not

impossible to find.

The TECnology

Hall of Fame is a continuing project,

with 95 inductees to date, with plans

to add more honorees in the’ future.

We encourage you to check out the inductees

from past years. Let’s all keep audio

history alive. And if you have any comments

or suggestions, let use know. We’ll

be listening.

George

Campbell/AT&T

First Audio Equalizer/Bandpass Filter

Electric Wave-Filter (1915)

George Ashley Campbell had a long and influential

career in developing technologies for the

audio, telephony and broadcast industries.

Born in 1870, Campbell graduated with a

B.S. degree from MIT and a master’s

degree from Harvard and joined AT&T’s

engineering department in Boston in 1897.

His initial research was in developing

means of improving the performance of long

distance telephone lines, which took the

form of inserting loading coils into phone

lines to avoid level losses and cut distortion.

Campbell later cited this research as part

of his doctoral thesis, which was awarded

by Harvard in 1901. Others—including

Michael Pupin and Oliver Heaviside— were

also involved in similar research, but

Campbell was first in creating a working

system and this application provided major

improvements in long distance telephone

quality.

Later, Campbell

focused much of his research on audio

filter development, creating the classic

L-C (inductor and capacitor) filters

that even today, are widely used in analog

tone control and filtering circuits. He

used the concept of combining simple high

pass (low cut) and high pass (high cut)

filters resulting in a more complex bandpass

filter, which was ideal for emphasizing

voice intelligibility over telephone lines.

These were accomplished using the now-classic “ladder

network” filters, so-called because

of their resemblance to ladders and documented

in Campbell’s 1915 patent application

(#1,227,113) for an “Electric Wave-Filter,” essentially

the first audio equalizer. Campbell’s

filter designs were later refined and expanded

by other AT&T researchers such as Otto

J. Zobel, who suggested a tunable “Wave

Filter” design in his 1921 patent

(#1,538,964). Beyond simple analog filtering

chores, the Wave Filter more importantly

paved the way for multiplexing—the

ability to run multiple voice conversations

over a single phone wire.

Ironically, this research for the modern

audio equalizer was completed years before

sound systems or even electrical recording

for records even existed. But the basics

of audio filtering had been laid and the

groundwork was ready to become part of

a revolution yet to come. George Campbell

died in 1954 at the age of 83, but had

been recognized by his peers for his four

decades of innovation. He was awarded the

IRE (Institute of Radio Engineers) Medal

of Honor in 1936, and four years later,

received the Edison medal by the American

Institute of Electrical Engineers.

|

Western

Electric 555-w compression driver

mounted

on

the end of the massive snail-coiled

Model 12-A horn. |

E.C. Wente & A.L.

Thuras

First High Frequency Compression Driver

Western Electric 555-w (1926)

There’s no doubt that 1926 marked

a busy era for audio technology. Electrical

recording—the use of microphones

and amplifier-driven cutterheads on record

lathes—was becoming a standard operating

procedure throughout the industry, and

the development of talking motion pictures

was underway. The industry suddenly needed

loudspeakers, with an emphasis on the word “loud.” A

year before, two General Electric engineers

(Chester Rice and Edward Kellogg) had unveiled

the modern dynamic cone loudspeaker, an

important step in the right direction.

However, with the low-power amplifiers

available at the time, any hope of providing

high-output reproduction was pretty much

out of the question.

Given that premise,

Edward C. Wente and Albert L. Thuras—two engineers from

Bell Laboratories—set out on a radical

solution. In a 1926 patent application

(#1,707,544), offered what they described

as “an acoustical device employing

an electrodynamic actuated vibrating element” using

a “light piston-type diaphragm which

is driven by a light rigid coil.” The

diaphragm/voice coil was set within a dense

electromagnetic structure fed a signal

from an amplifier and was designed to mount

onto a horn.

The resulting

product was the Western Electric Model

555-w “receiver,” and

the modern high frequency compression driver

was born. It’s surprising how close

the 555-w came to modern designs and how

little things have changed since then.

The original Wente-Thuras design featured

innovations such as a lightweight 0.002-inch

thin aluminum dome diaphragm with a corrugated

surround offering strength, stiffness and

flexibility; a phase plug; and a threaded

horn mount that allowed the driver to be

easily fitted on a variety of horns. The

picture shows the 555-w mounted on a Western

Electric Model 12-A, a huge, exponentially

tapered horn design that was 67 inches

tall, with a 45x45-inch throat opening

and an 11-foot overall pathway that provided

a frequency response as low as 80 Hz. Although

bulky, the driver/horn combination proved

highly efficient, and could achieve high

sound pressure levels from low-powered

amplifiers and could be used alone or combined

with cone woofers for extended low- frequency

performance.

|

Lansing Manufacturing

Iconic

monitor with top-mounted

multicell

horn/compression driver

and power

supply for supplying

voltage to the

speaker field coils. |

James B. Lansing/Lansing Manufacturing

Co.

First Recording Studio Monitor

Lansing Iconic (1937)

James B. Lansing founded Lansing Manufacturing

Company in 1927, initially to supply small

6- and 8-inch loudspeakers for radios.

With the ever-improving fidelity of home

radio sets, the company did well, but as

talking motion pictures became established,

Lansing was drawn to the challenge of building

extended–range loudspeaker systems

for film sound playback. In 1934, he supplied

15-inch woofers, compression drivers and

manufacturing expertise for the development

of Shearer Horn, the first large-scale,

high fidelity system for theater sound

reproduction.

Lansing later

turned to developing a monitor for film

mix stages, resulting in the Monitor

System 500, a single-15 driver in a folded-horn “W” box

with a sizeable model 805 multicellular

horn. Although a quarter the size of the

gargantuan Shearer Horn, the 500 was still

too large for most recording facilities.

With that in mind, Lansing began creating

the first recording studio monitor.

Developed in

1937, the Lansing Iconic was a compact

(about 40x25x18-inch) two-way system

with a 15-inch model 815 woofer in a

vented, bass reflex enclosure crossed

over at 800 Hz to an 801 compression driver

on a 808 multicell horn, for a response

that went from 30 Hz to 15k Hz and was

rated as flat (±2dB) from 45 to

10k Hz. Both drivers were electrodynamic

field coil (electromagnet) designs, requiring

an external power supply. Later models

were available with permanent magnets,

as well as “Salon” home versions

in furniture-style cabinets and component-only

kits for custom installations.

The Lansing Iconic was well-received among

recording and sound-reinforcement users

and remained in general use well into the

1940s and beyond. Among the many fans on

the Iconic system was Les Paul, who used

them in his recording studio.

Alec Harley Reeves

Pulse Code Modulation Patent (1939)

Discoveries occasionally occur long before

the current technology is ready to accept

and support it. And this is certainly the

case with British physicist Alec Harley

Reeves, who proposed one of the cornerstone

principles of digital audio, Pulse Code

Modulation (PCM), more than four decades

before introduction of the first commercial

digital audio recorder.

In his 1939 patent

for a “Signaling

System,” Reeves describes his invention

as a “system for transmitting complex

waveforms—for example speech—wherein

the waveform is scanned at the transmitter

at predetermined instants” and the “amplitude

range of the waveform to be transmitted

is divided into a finite number of predetermined

amplitude values according to the fidelity

required.” He also proposed a tube-based

PCM circuit, but this was in 1939—well

before the introduction of transistors,

ICs or microprocessors—and due to

the limitations of available technologies,

Reeves PCM proposal remained mostly unused

until the 1950s, when it was employed into

low-fidelity applications such as telephone

systems.

During World

War II, Reeves turned his efforts to

defense projects and proposed the OBOE

bombsight system used by the Royal Air

Force. Reeves authored dozens of patents

during his life and in latter years, he

was part of the research team at Standard

Telecommunications Laboratories that perfected

the use of fiber optics made from low-loss

glass. In 1969, 30 years after Reeves’ patent,

the British government honored PCM’s

role in advancing telecommunications technology

with a postal stamp. Reeves died in 1971

at the age of 69.

|

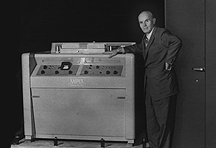

Ampex

VRX-1000 with company

president Alexander

Pontiatoff |

Ampex Corporation

First Commercial Video Recorder

Model VRX-1000 (1956)

Technology is often filled with irony,

and the interesting part about the development

of the first commercial video recorder

is that its roots hail from audio innovators.

In fact, the concept stems from Bing Crosby’s

audio engineer Jack Mullin, who brought

the first German tape recorders to recorders

to America after World War II. Mullin demonstrated

them to Crosby, who fronted the capital

to Ampex to begin building audio tape recorders

in 1946. Four years later, with the advent

of television, Mullin talked to Crosby

about the notion of recording TV programs

on tape. A research project began, resulting

in a clunky—although functional—experimental

system with tape running over fixed heads

at 100 ips. Similar projects were also

underway at RCA and at the BBC.

In 1952, Ampex

began its own VTR project, with Charles

Ginsburg leading a team that included

Charles Anderson, Alex Maxey, Fred Pfost,

Shelby Henderson and the youngest member

of the team, a 19-year old kid named

Ray Dolby. But rather than a fixed-head

approach, Ginsburg was interested in pursuing

the (now-standard) concept of rotary tape

heads, proposed by engineer/inventor Marvin

Camras. The VRX-1000’s four tape

heads whirling at 14,400 rpm yielded a

tape speed equivalent to a fixed head deck

running at 1,500 ips, and could handle

the wide bandwidth requirements of video.

A 10-inch reel of 2-inch tape (the team

settled on using a 3M formulation) could

record 45 minutes and the VRX-1000 debuted

at the NATRB (later known as the NAB) show

in Chicago on March 14, 1956.

The first production unit (shown prior

to shipment in photo with Ampex founder

Alex M. Pontiatoff) was sold to CBS who

used the deck for tape-delay broadcasts

of news broadcasts in November of 1956.

Although the VRX-1000 cost $50,000 (an

enormous sum in the mid-1950s) and fewer

than 20 VRX-1000s were built, one thing

was clear. The days of live broadcasts

were numbered, and broadcasting and television

production would never be the same.

|

Sennheiser MD

421 |

Sennheiser

MD-421 Microphone (1960)

Introduced in 1953, Sennheiser’s

MD 21 (“mikrofon dynamische” )

dynamic microphone was perhaps one of the

company’s most successful products.

Rugged, reliable, good sounding and available

in available in five colors, it was a hit

with European broadcasters and remained

in production for decades. However, the

basic, no-frills MD 21 was an omnidirectional

model, so in 1959, company founder Dr.

Fritz Sennheiser worked with his design

engineers Paul-Friedrich Warning and Johann-Friedrich

Fischer to take the design to the next

step.

The project was the MD 421, a rugged dynamic

mic that could provide a tight cardioid

directivity pattern that was consistent

at nearly all frequencies. It also featured

the capability to handle extremely high

sound pressure levels (up to 175 dB!),

a hum compensation coil to prevent EMI/RFI

interference and a 5-step low-frequency

attenuation circuit for tweaking bass response.

The MD 421 had to provide studio-quality

frequency response (30 Hz to 17 kHz) and

be able to be manufactured in relatively

large quantities. It was a tall order,

but the development team went to work.

In most studio (or live sound) mic designs,

the capsule and electronics are the most

difficult part of the design process, but

with the MD 421, extreme attention was

also paid to controlling low frequency

directivity and assuring consistent polar

response. This was accomplished using four

rear vents near the rear of the mic, felt

damping at the rear of the mic body, internal

damping within the capsule and a bass pre-emphasis

tube that provided airflow between the

capsule interior and a large air chamber

within the mic body. A cutaway diagram

of a MD 421 reveals the complexity of a

design that resembles a jet engine more

than a dynamic microphone.

The MD 421 body was made of DuPont Delrin

polymer resin, which had just become available

the year before and 50 years later, the

MD 421 remains one of the few professional

audio microphones featuring a molded (now

glass composite) body.

The MD 421 was

launched at Germany’s

Hannover Fair in 1960 and carried a price

tag of 180 Deutschmarks (about $45 USD).

The original version was available with

Tuchel or DIN output connectors; an XLR

version followed years later. But in any

version, the MD 421 was an instant success.

In fact at one time, the backorder situation

was so extreme that Sennheiser ran ads

with a bakery worker posing with trays

of mics coming out of the oven, to assure

customers and dealers that more MD 421s

were on the way.

Today, five decades years after its introduction,

the MD 421 remains in use worldwide in

broadcast as a vocal microphone and in

studios mostly as an instrumental microphone

capturing percussion, drums, guitar amps

and horns. The current incarnation of the

MD 421, the next-generation MD 421-II,

incorporates improvements such as a metal

inner chassis for better weight distribution,

a shorter, sleeker housing and self-sealing

(non-adhesive) acoustic connections for

improved serviceability. And with some

500,000 units in use since 1960, the MD

421 has definitely earned the well-deserved

distinction of an audio classic.

|

Sequential

Circuits

founder Dave Smith with

Prophet-5 |

Dave Smith

First Polyphonic Programmable Synthesizer

Sequential Circuits Prophet-5 (1978)

Once in a while a product comes out that

puts it all together—combining the

latest technology, while breaking new ground

and at the same time, filling a definite

void in the market. And as the first programmable

polyphonic music synthesizer, the Sequential

Circuits Prophet-5 was exactly that. An

analog synthesizer with the ability to

play five notes simultaneously (enough

for a chord) and having the memory capability

to store a whopping 40 preset programs

(later expanded to 120) might not create

headlines today, but the Prophet-5 was

a sensation in its time, and is still considered

a classic.

The path to success

wasn’t easy.

Sequential Circuits founder/chief designer

Dave Smith was excited about the prospect

of combining the sound generation capabilities

of the new ICs from Solid State Music (SSM)

that reduced the major functions of analog

filters and synthesis (VCO, VCA, VCF) into

single chipsets, reducing the number of

necessary components in an synthesizer

circuit from hundreds to a few handfuls.

At the same time, new microprocessors had

just come to market (such as the 8-bit

Zilog Z80), which while primitive by today’s

standards could definitely handle tasks

such as storing/recalling synth patches.

Once the ingredients were in place, Smith

worked with John Bowen (now of John Bowen

Synth Design) and with some consulting

help from E-mu founder Dave Rossum, the

Prophet-5 project was underway, and was

completed in just six months—an amazing

accomplishment.

On its debut

at the Winter NAMM show in January 1978,

the Prophet-5 was nothing less than a

hit. The SSM chips (later replaced with

Curtis ICs), combined with Smith’s

autotuning circuit kept the Prophet-5 in

tune—a problem that plagued many

early analog synths. Of course, its ease

of operation, great factory patches of

thick bass and lead sounds, and lush analog

string pads made the Prophet-5 quite desirable—even

at an original retail of $3,500 (later

$4,500). Soon every top keyboardist either

owned one—or wanted one—and

the Prophet-5 sounds became a common fixture

over radios everywhere, from punk bands

to Michael McDonald’s signature sound

on hits like the Doobie Brothers’ “What

a Fool Believes.”

The Prophet-5 stayed in production until

the mid-1980s and sold approximately 8,000

units. Today, Dave Smith continues creating

award-winning analog synthesizers with

his company, Dave Smith Instruments.

|

Future Sonics

Ear Monitors™ |

Marty Garcia

First Commercially Available In-Ear Monitoring

System

Future Sonics Ear Monitors (1985)

The application

of headphone monitoring by onstage musicians

has been in use since the early 1970s.

These were mainly used by drummers, but

also by innovators such as Doobie Brothers

guitarist Jeff "Skunk" Baxter,

who found that headphone use in live

performance not only provided him with

improved listening but also protected

his hearing from excessive stage volumes.

The concept was good, but clunky headphones

weren't exactly the ideal solution. In

1978, inventor Steve Ambrose designed

and built the first in-ear monitoring

system, created as custom products for

Stevie Wonder and other top artists.

Several years

later, Marty Garcia—a

live sound engineer who operated Philadelphia-based

Crystal Sound and mixed hundreds of shows—experimented

using earpieces carrying a personal monitor

mix. Garcia began using consumer earbuds,

but after trials with a variety of top

performers, saw the opportunity for a more

specialized approach, and starting working

with audiologists to supply custom ear

molds.

In 1985, Garcia

was developing and refining his designs

for Ear Monitors® and Ears™-brand

earphone monitors. That same year, Todd

Rundgren used Future Sonics products on

his Utopia tour, the first wedgeless stage

with all band members wearing Garcia’s

Ear Monitors. Garcia founded Future Sonics

in 1991 and the word about his Ear Monitors

spread, with major artists such as Phil

Collins, Steve Miller and The Grateful

Dead joining the company’s growing

list of users.

Today, the use of earphone

monitoring is standard throughout the industry,

offering the advantages of reduced freight

requirements (by eliminating the need for

onstage wedges and sidefill speakers),

cleaner stages, lower onstage volume and

better monitor mixes for performers. And

the key to this revolution was Marty Garcia

of Future Sonics.

|

Waves

founders Gilad Keren and Meir Shaashua |

Gilad Keren & Meir

Shaashua

First Audio Plug-In

Waves Q10 Paragraphic Equalizer (1992)

The concept of plug-ins—additions

that add functionality to established programs—date

back to text editors running on Univac

mainframes in the 1970s. By 1991, plug-ins

came on the scene, mainly as filter effects

sets for paint and photo manipulation software,

notably Digital Darkroom and Photoshop.

And although few realized it at the time,

the audio world was about to see some rather

significant changes in the years to come.

At the AES show in 1992, a new company

called Waves unveiled what was the first

audio plug-in. Created by founders producer

Gilad Keren and musician Meir Shaashua

(both also having extensive backgrounds

in math and engineering studies), the Q10

Paragraphic Equalizer was a little before

its time, but laid the groundwork for nearly

two decades of future success for the young

business. In addition to being the first

audio plug-in, the Q10 was groundbreaking

in other areas, offering quality that rivaled

or exceeded hardware units, while automating

complex filter coefficient calculations

and offering a clear, simple to use screen

interface.

The Q10 was anything

but an immediate success, but this was

hardly the fault of the product itself.

It ran on Digidesign’s

Sound Tools and early Pro Tools systems

where only a single plug-in could run at

a time. Two years later, the advent of

TDM (the open-architecture, 256-channel,

24-bit digital audio bus for Pro Tools)

opened the possibility of multiple plug-ins

on a single session and software-based

signal processing began evolving into an

integral part of modern audio production.

Today, Waves

(still with Keren and Shaashua at the

helm) has become a leader in digital

signal processing for the music recording,

gaming, live performance, broadcast and

film/video post-production industries.

And the Q10 that started it all is still

going strong (now updated to support TDM,

RTAS, Audio Suite, VST and AU platforms

and 24-bit/192kHz resolution) and is a

component in the company’s high-end

production bundles.

Dr. Harold Hildebrand

Antares Auto-Tune (1997)

Antares Audio Technologies was originally

founded in 1990 as Jupiter Systems by Dr.

Harold “Andy” Hildebrand, a

geophysical scientist who developed the

first standalone workstation for seismic

data interpretation. After nearly 14 years

in that industry, Hildebrand turned his

focus to merging his knowledge of DSP with

audio and music composition. Jupiter’s

first product was Infinity, an advanced

looping program, followed by 1994’s

MDT™ (Multiband Dynamics Tool), one

of the first commercial plug-ins for Digidesign’s

Pro Tools.

The huge breakthrough

came in 1997 with the launch of Antares

Auto-Tune plug-in (followed by a hardware

rack version) that could correct pitch

problems in vocals and other solo instruments.

Auto-Tune quickly became the best selling

audio plug-in of all time, and once the

general public became aware of it, the

technology was embroiled in controversy.

The erroneous impression was that automated

pitch correction meant that anyone could

perform with perfect pitch, leading to

the ruin of true music performance. However,

Auto-Tune was simply another production

tool, hardly different that punching

in a passage 75 times until it’s right, or �“comping” a

final vocal/solo by combining different

takes or using cut-and-paste editing to

replace a flawed chorus with a good one.

In fact, having

a pitch corrector in the vocal chain

can serve to enhance a vocal (live or

studio). By providing a musical “safety

net,” a performer could concentrate

on the overall performance without worrying

about that one tricky note, resulting in

a better take, even without the Auto-Tune

kicking in. And in a live setting, any

real performance is preferable to the lip-synced

vocal playbacks on many tours today.

Today Auto-Tune

is in its seventh generation and now

offers both pitch- and time-based correction.

And more than a decade later, it’s

more popular than ever, not only for

fixing a note or two, but sometimes also

used “turned up to 11” to

provide an exaggerated perspective on instruments

and vocals—such as the iconic Cher/T-Pain-style

Auto-Tune effect—or in a completely

different vein, to bring musicality to

a narrated vocal track.

TECnology Hall

of Fame director George Petersen is also

the executive editor of Mix magazine

and an engineer/producer who’s

most recent project is “Voodooville:

A Celebration of New Orleans,” a

5.1 surround-audio DVD of jazz/funk/blues/Creole

music.

home | sitemap

| contact |